Sustainable and Versatile Additive for Rheology Modification of Liquid and Structuring of Solid Detergents

Today's trend towards more sustainable detergents translates into a need for biodegradable and biosourced materials that perform well in the target applications.

One of the approaches to enable more sustainable products relies on high yield additives, such as rheology modifiers or structurants.

Those additives helps to do more with less; lower levels of active ingredients, same performance at reduced cost, concentrated formulations.

Dow Home care technical team have designed a new bio-based, biodegradable technology, SupraCare™ 780 Additive which would be a perfect fit.

The present study will demonstrate how to use this new material to obtain optimum rheology in liquid formulations and high water structuring and retention across solids formats with reduced levels versus current materials. -> back to main page

Introduction

Cellulosic rheology modifiers are present on the market for a long time. They are known in Home Care primarily for their rheology modification properties. Examples of Cellulosic include Hydroxyethyl cellulose, Hydroxy propyl methyl cellulose and cationic hydroxyethyl cellulose for providing conditioning benefits.

SupraCare™ 780 Additive is a cellulose derivative combining rheology and structuring benefits. It is a technology that provides an unprecedented level of water structuring to solid formats (soap / shampoo bars, laundry washing pearls). This allows producers to reduce the dosage of palm oil derivatives by up to 20%, resulting in lower formulation cost in extremely cost-conscious category and sustainable formulations.

Dow’s unique branching technology platform for Supra-Care™ 780 Additive provides unrivaled efficiency in solids and liquid formats application.

SupraCare™ 780 Additive is added in solid formats to significantly improve water structuring (c.a. 30%) of soap bars, laundry washing pearls. The new Cellulose ether (CE) structure’s the mortar phase leading to regained cohesion ultimately resulting in high water structuring which otherwise is impossible to attain. Water structuring by CE depends on polymer molecular mass which is determined by that of cellulose raw material used for

etherification. Cellulose raw material is obtained from natural sources and so control over the molecular mass is limited. This also limits the molecular mass of CE – and consequently its maximum water structuring capability.

SupraCare™ 780 Additive provides an unprecedented level of water structuring allowing formulators to lower dosage even relative to commercial high viscosity CE. Introduction of Dow branching technology overcomes historical limitations for water structuring of CE due to molecular weight limitations of naturally sourced cellulose raw material. SupraCare™ 780 is inherently, -ultimately biodegradable (greater than 70% as per OECD 302B test method).

SupraCare™ 780 Additive benefits in a nutshell:

- High thickening efficiency

- High electrolyte tolerance

- High compatibility due to non-ionic nature

- Structuring and binding properties

- Foam boosting

- Reduced mushiness in detergent bars

- Derived from natural raw materials

- Inherently, - ultimately biodegradable as per OECD 302B

SupraCare™ 780 Additive addresses need across various applications:

In Liquid formats it can be used in the following formats:

- Hand Dish wash liquid

- Liquid laundry detergents

- Hard Surface cleaners

- Fabric conditioners

In solid formats it can be used in the following:

- Laundry bars

- Multi-purpose bars

- Non-soapy detergent (NSD) bars

- E-commerce friendly formats

- Detergent tabletsToilet cistern blocks

Materials & Methods

Subject and study design

In this first study SupraCare™ 780 Additive was evaluated as a rheology modifier in hand dish washing liquid formulations and as a high-water structuring agent in solid formats like soap bars or laundry washing pearls.

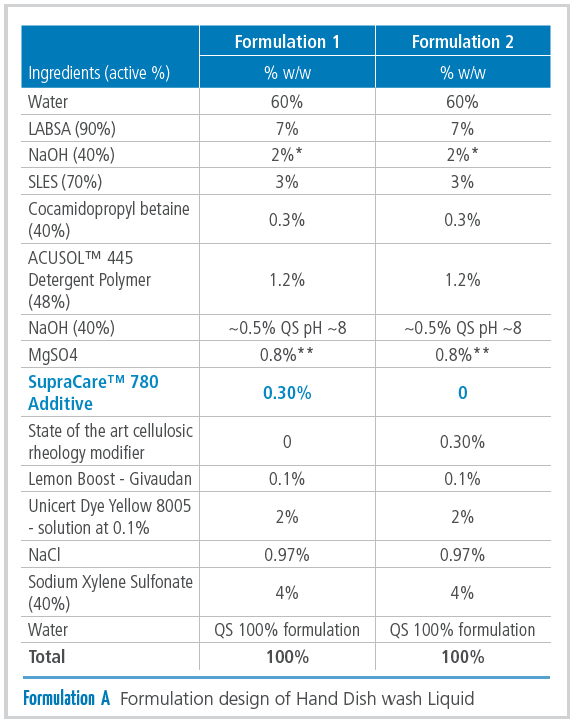

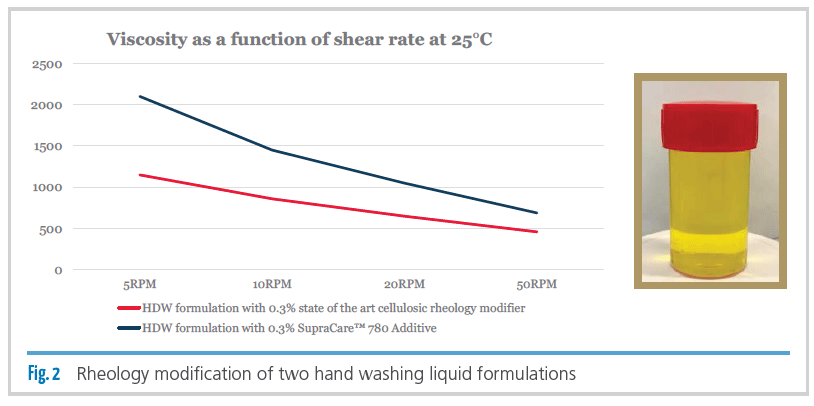

The hand dish washing liquid with SupraCare™ 780 Additive was compared under identical test conditions with the stateof-the-art rheology modifier by designing two separate hand dish washing liquid formulations.

Formulation was processed in the lab using a variable speed overhead stirrer and the order of ingredients were added as listed in the Formulation A.

2.1 Formulation design of Hand Dish wash Liquid

Viscosity is measured with viscometer Brookfield RV DVII Plus CP52 successively at 5, 10, 20 & 50RPM with temperature fixed at 25°C.

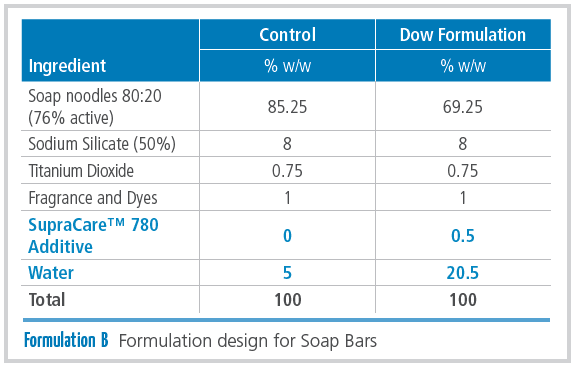

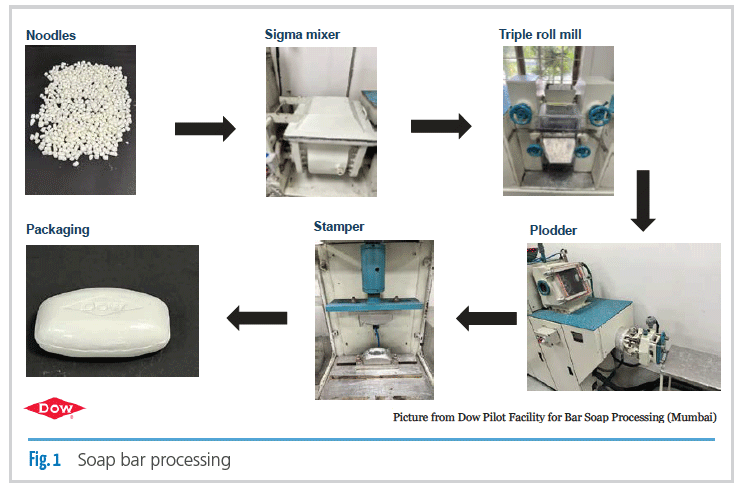

In solid formats like soap bars, formulations containing SupraCare™ 780 Additive as listed in Formulation B, were compared with control formulations and various consumer relevant attributes like rate of wear, foam, cracking, longevity of the bar, water structuring, and retention were assessed. In soap bars 80:20 soap noodles were used in the formulation with the following processing route as depicted in Figure 1.

Rate of wear assessment for soap bars

A trained panelist evaluated the laundry bars prepared according to the below formulations to assess the wear rate as the percent weight loss from the laundry bar after 4 days of use using the following test protocol. Take poplin cotton of

fabrics of 20 cm x 15 cm immersed in water. Weigh the cleaning bars initially (each laundry bar composition is tested in triplicate). Scrub the bars 10 times with the top and bottom surface of the bar on the fabric surface. In total there will be 20 scrubs per laundry bar. The process is repeated five times per day for each cleaning bar (i.e., 100 scrubs per cleaning bar per day). This is continued for four consecutive days. On the fifth day the cleaning bars are weighed with the average wear rate.

2.2 Formulation design for Soap Bars

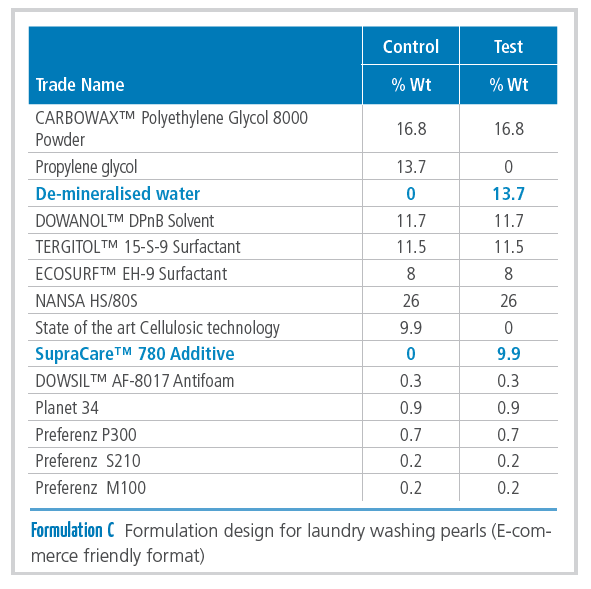

2.3 Formulation design for laundry washing pearls (E-commerce friendly format)

The laundry washing pearls as listed in Formulation C, were processed through the following route:

- Weight CARBOWAX™ Polyethylene Glycol 8000 Powder, start heating at 80°C under shear (200rpm) with 4 blades propeller.

- Add solvent and surfactants successively in the beaker. Add Progressively SupraCare™ 780 Additive.

- Reduce temperature to 60°C then add perfume and enzyme.

- When the blend is homogeneous, pour into molds.

- Let the pearls solidify, remove from molds and let it dry for 24h.

Results and Discussion

In the rheology studies for the hand dish wash liquid formulation as shown in Figure 2 we can clearly perceive addition of SupraCare™ 780 Additive demonstrates higher viscosification efficiency. SupraCare™ 780 Additive effectively increases viscosity outperforming the state-of-the-art cellulosic rheology modifier. Addition of only 0.3% is enough to thicken hand dishwashing liquid based on 10% of surfactants while acheving a transparent formulation.

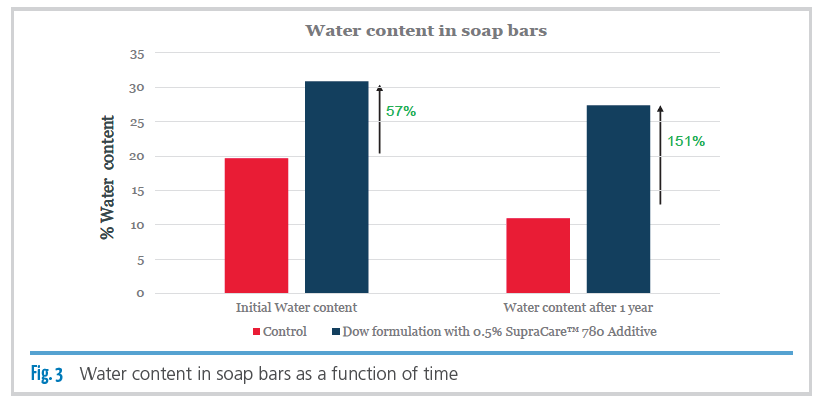

In the soap bars SupraCare™ 780 Additive enables high water structuring and retention as illustrated in Figure 3.

SupraCare™ 780 Additive helps to bind more water while maintaining the bar characteristics. Lower TFM (Total fatty matter) can translate into reduced formulation cost. SupraCare™ 780 Additive helps to retain more moisture content in the soap bar as a function of storage time.

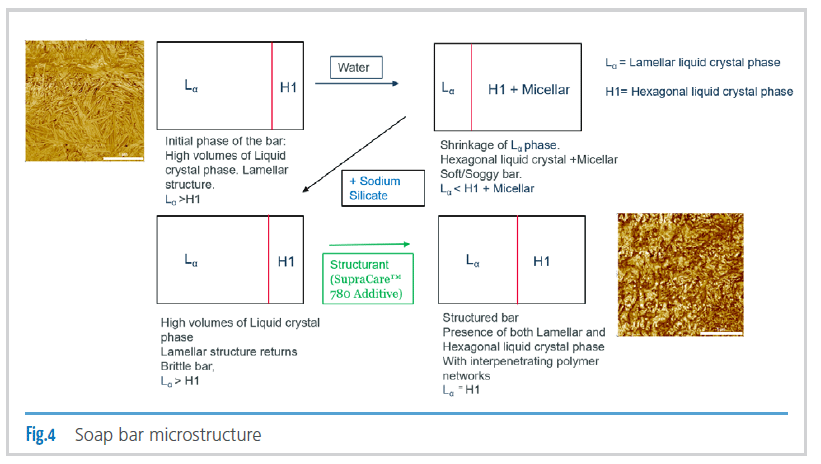

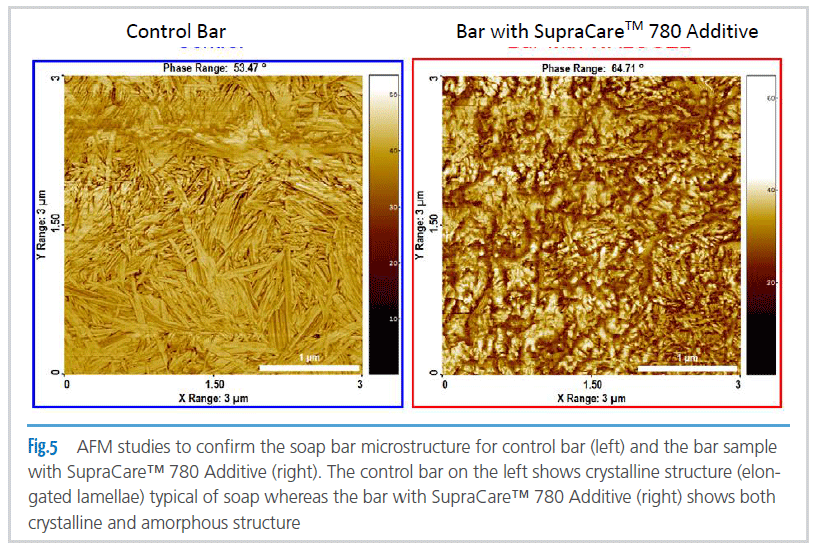

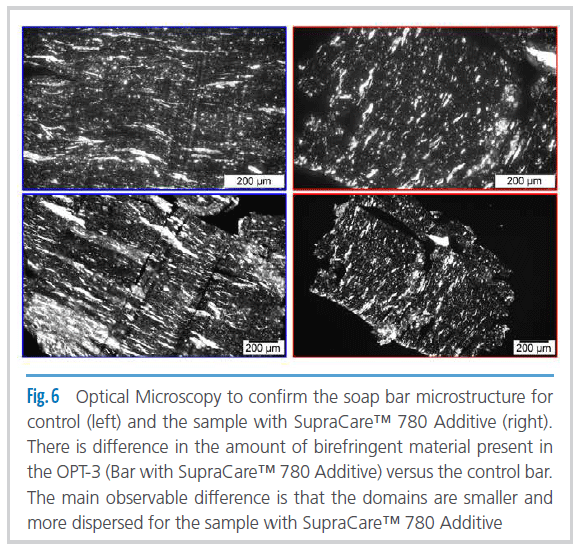

Solid formats have a brick-andmortar structure as illustrated in Figure 5 and 6. The brick is the hard phase responsible for the structure and the mortar is the liquid phase responsible for lather and mush. Brick phase consists of the sodium stearate/PEG and the mineral (part), the mortar phase consists of sodium laurate, sodium oleate, sodium palmitate, water, glycerin, electrolyte, mineral (part) and perfume.

The initial bar will have a percolated brick structure (liquid crystal phase) with continuous mortar phase as shown in Figure 4. When we add more water the bricks shrink, mortar is diluted, and the percolated structure is compromised which softens the bar. When we add sodium silicate the bricks grows, mortar is diluted, percolative structure returns, but the lack of cohesive force leads to brittle or crumbling bars. It was discovered that a SupraCare™ 780 Additive was able to structure the mortar phase leading to regained bar cohesion and thereby leading to high water structuring which otherwise is impossible to attain.

The working hypothesis is that SupraCare™ 780 Additive molecules form large agglomerates in an aqueous environment that block capillary pores in the soap bar matrix, thus slowing down loss of water. It was further proven by AFM that incorporation of CE leads to growth in both crystalline and amorphous phases leading to more water structuring. The distribution of the liquid crystal (LC) domain in the soap was shown by polarized light microscopy. Addition of water led to the loss of liquid crystal phase. SupraCare™ 780 Additive incorporation likely removed the water from the mortar phase and resulted in an increase in volume of the liquid crystal (LC) domain. Using pulse field-magic angle spinning NMR it was shown that inclusion of SupraCare™ 780 Additive in the soap bar formulation reduces the variation in water diffusivity improving the morphological integrity ofsoa p bars with higher water content.

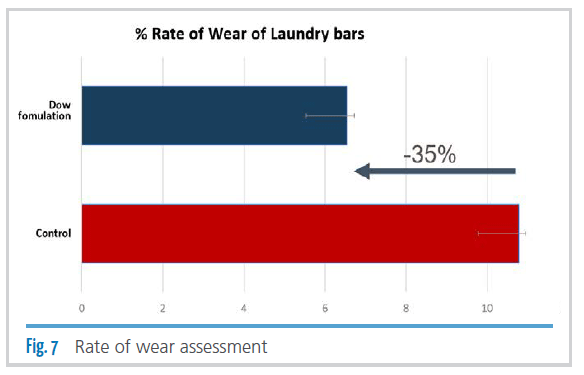

SupraCare™ 780 Additive enables longer lasting bars as is evident from the rate of wear assessment studies depicted in the following Figure 7.

Significant reduction of the rate of wear by around 35% was observed, an indication that the bars containing SupraCare™780 Additive would last longer.

SupraCare™ 780 Additive helps to generate more foam (by ca 10%). Foam is one of the most important attributes of the laundry bars connecting a visual cue with an impression of cleaning action.

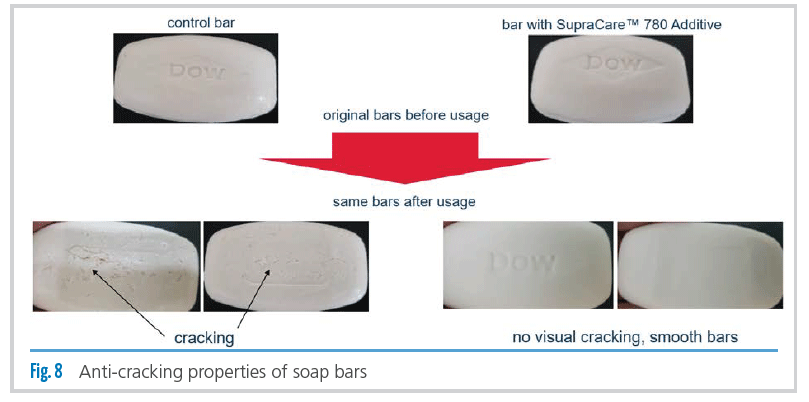

SupraCare™ 780 Additive prevents soap bar cracking by acting as a structurant leaving the bars smooth and without cracks as shown in Figure 8.

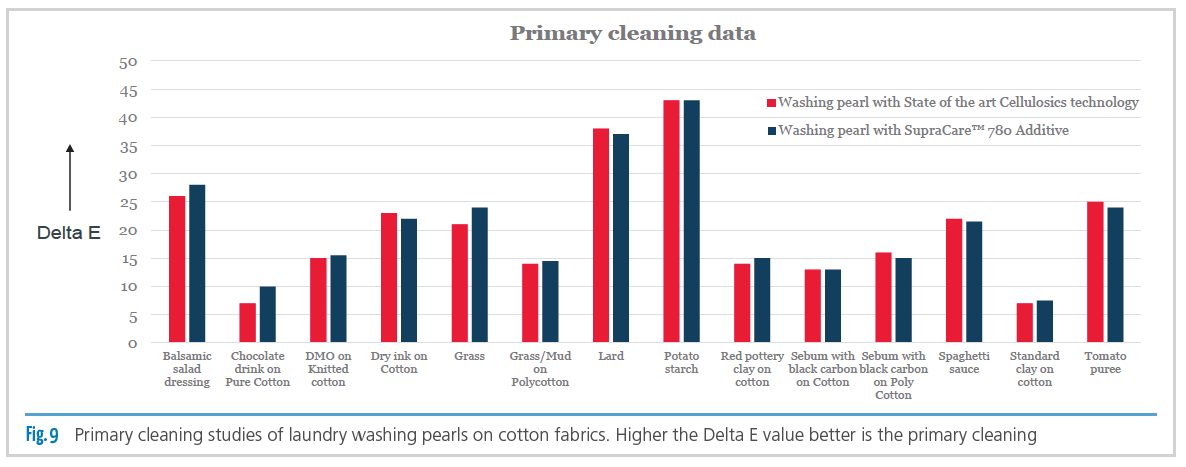

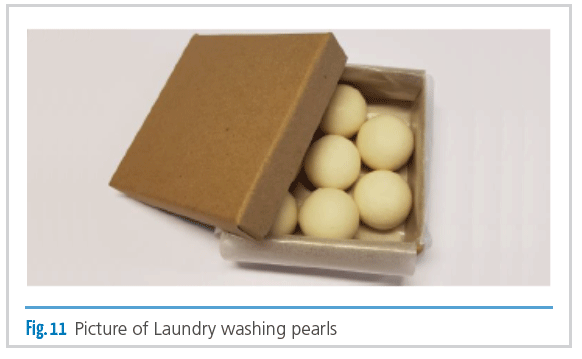

In laundry washing pearls, a popular format for e-commerce, as illustrated in Figure 11. SupraCare™ 780 Additive enables cost reduction through complete replacement of propyleneglycol with equivalent benefits onprimary cleaning as illustrated in Figure 9.

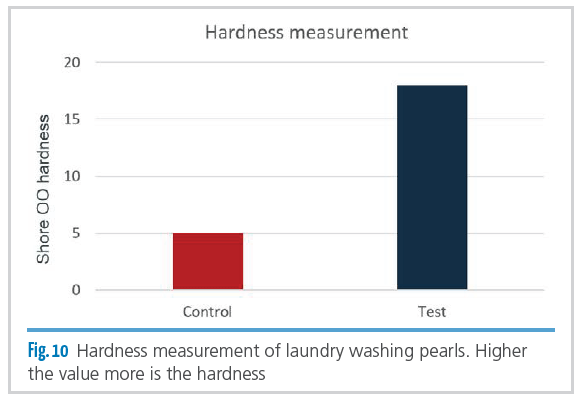

The Shore D hardness measurement illustrated in Figure 10, indicates that SupraCare™ 780 Additive (Test) provides optimal water structuring and binding of the laundry washing pearls. SupraCare™ 780 Additive enables higher water content helping to reduce cost. It also makes the pearl hard enough so that it doesn’t crack and dissolves faster.

Conclusion

- High thickening efficiency (yield) and good compatibility for modifying rheology of liquid detergents such as hand dishwashing liquids or laundry liquids

- Structuring and binding properties connected with foam boosting to ensure improved detergent bar properties

- Derived from natural raw materials, its inherently, ultimate biodegradability helps the formulator to design more sustainable products

Authors

1 Saugata Nad*, Serge Creutz, Christel Simon, Rahma Benbakoura, Flore Vandemeulebroucke

2 Deepak Dandekar | 3 Paweł Chojnacki

1 Dow Silicones Belgium SRL

2 Dow India | 3 Dow Poland

*Corresponding Author: [email protected]